Lenwa aluminium C profiles are special items used in various projects. They are very versatile and can be used in various ways. Because they are light, though, they are also strong in that regard of perfect for building stuff. This article will discuss benefits of aluminium C profiles and explain why they should be considered for next project. They aluminium door profile can be shaped more easily and for this reason aluminium C profiles can be used in many ways. Perfect for so many projects, you can bend them into all types of shapes! If you are constructing a new house or assembling furniture aluminium C profiles could help you create a robust and enduring project.

Lenwa aluminium C profiles are lightweight but very strong. Aluminium is a metal that despite of being light weight is strong. Aluminium C profiles are also great for projects where strength is important but weight is also a factor. Countless profile aluminium things you can do with these to strengthen your project while not weighing it down so much it becomes impossible to carry.

What are all the benefits of using aluminium C profiles for your projects? The first is that they are simple to work with as you can bend and shape them easily. Since you are not limited profiled aluminium to one style. Furthermore, they are extremely durable and have a long life so your project will be permanently strong. Last but not least, aluminium C profiles drive on the cheaper end as well, therefore they are a safe option for projects requiring budget constraints.

Lenwa aluminium C sections are ideal for construction Al sections are very resistant and strong making them an ideal construction material. In doing so, they can ensure solid buildings which go on for years to come. They also resist aluminium trim edge rust and corrosion, making them useful for outdoor projects or where it’s damp. Another reason to use aluminium C profiles is that they can be recycled so they are good for the environment as well.

Aluminium C profiles have numerous applications. Finally they are used in construction for manufacturing strong frames. They are used in manufacturing to produce parts for machines and equipment. They are also used in the automobile industry to create lightweight, strong components for cars and trucks. You can use aluminum angle trim to add strength to any project you are working on.

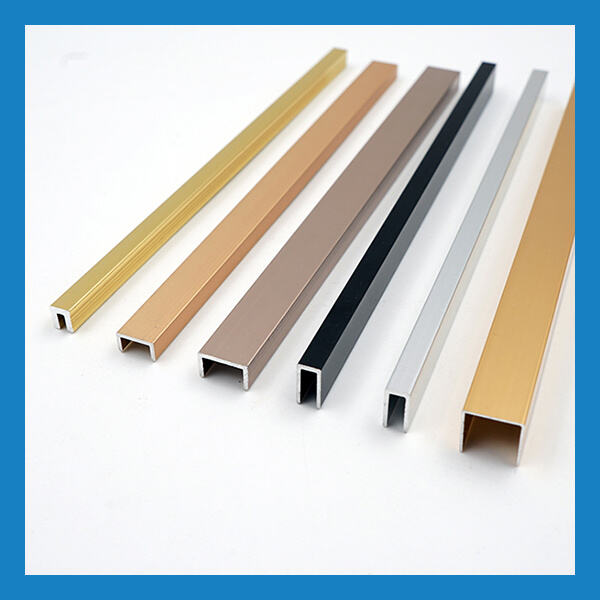

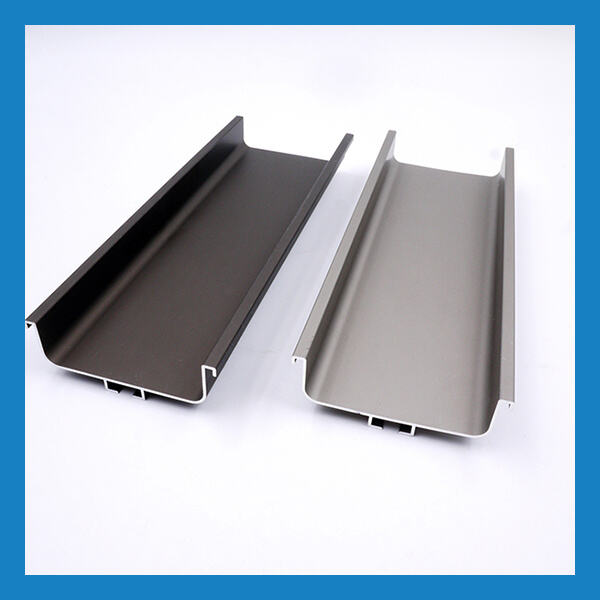

have over 20 years experience aluminum extrusion surface treatment manufacturing aluminum profiles. From precise extrusion, precise finish Aluminium c profilelike anodizing, powder coating, wood grain effects, our expertise ensures every product meets the highest standards in terms of durability and quality.

commitment to personal service, offer custom mold development aluminum profiles that are based your drawings or samples, ensuring Aluminium c profileintegration with specific needs of your. Our wide range of precision solutions, such as CNC milling and punching, threading, and bending, lets make every part of your plan to the highest quality. We offer a wide range of customizable options, ranging from intricate designs to precise specs.

From home decoration profiles architectural parts, diverse product range covers a variety of industries applications. If you're looking conventional profiles or bespoke solutions, our broad portfolio ensures that you'll find the right fit your specific project needs. We are committed to quality and innovation, and we Aluminium c profileenhance and develop our products in order to meet the needs of our customers.

have an unparalleled manufacturing infrastructure, including 8 lines aluminum extrusions, 1 powder coating Aluminium c profileline and dedicated anodizing wood grain production lines. We also have a workshop with 3 CNC machines as well as numerous special equipment. comprehensive setup ensures precise efficient production to meet the different needs of our clientele.

ONLINE

ONLINE