Anodized Aluminum profile is a special quality of Aluminum that undergoes an exclusive chemical process to create the oxide layer on its surface, along with Lenwa's product aluminium h section. The latter gives it a very appealing appearance, in addition to the qualities of strength and rust resistance which are so important. In this article, we are going to explore the other dozens of reasons why anodized Aluminum profile squeezed into the category of metals.

Anodized Aluminum profile is very much advantageous that makes it an ideal choice in comparison to other metals. It is lightweight and easy to work with, which makes it a common material for all sorts of things. Second, it is ideal for industrial applications since brass has a long lifespan and can withstand corrosion. Lastly, its ability to withstand the harshest environmental elements and UV radiation means that it is perfect for outdoor projects. More so, anodized Aluminum profile features superior conductivity and reflectivity when it comes to electricity and heat respectively making them a material of choice featuring in the world of electronics.

Aluminum industry has seen a boom into invention and the conversation was mostly concerning anodized Aluminum profile along with also different derivatives of aluminium, just like the extruded shape made by Lenwa. Aggressive R&D efforts uncovered new performance and flexibility The deep research that was done resulted in finding many ways to improve the capabilities of Aluminum. For example, the invention of Aluminum alloys with high strength and rigidity made it possible to build complex structures and machines. Advancements in the anodizing process also produced a metal with superior corrosion resistance and shine.

The anodized Aluminum profile has emerged as a safe leading and health-conscious alternative for the fabrication of all types of products or structures, same with Lenwa's curved aluminum extrusion. Such as magnetite, it does not release any harmful gas or toxin making Aluminum safe for use in many applications. Moreover, anodized Aluminum profile does not contain hazardous dyes that are capable of provoking skin sensitization and even respiratory problems.

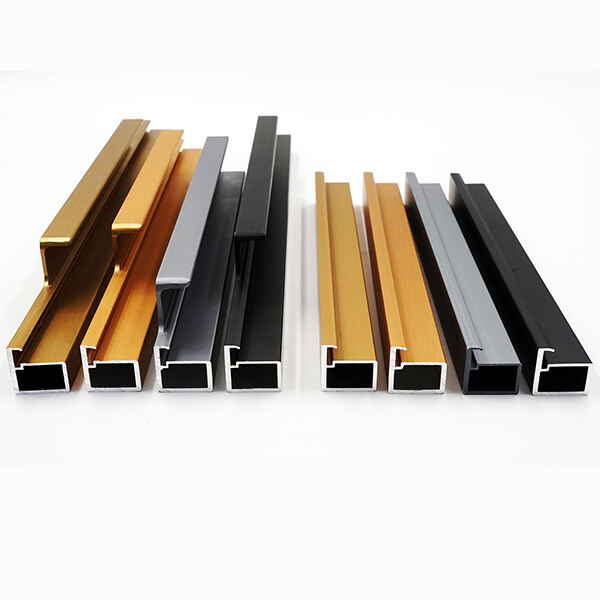

Anodized aluminium profile being such versatile is used in a whole range of products, also the curved aluminium profile from Lenwa. It is highly adaptable for manufacturers to mold anodized Aluminum profile in a variety of sizes and shapes according to the needs of their customers. Curtain and window frames, railings, furniture frameworks, cabinets are some of the examples that can be made using anodized Aluminum profile.

The success of any project that includes utilizing this metal depends on the quality of anodized Aluminum profile used, similar to the Lenwa's product like oval aluminum pipe. Making anodized Aluminum profile in high quality lies on the right process of anodizing. If the specified process is not followed, it may lead to formation of a brittle Aluminum profile having less anodic oxide layer bonding with the substrate material and becomes rapidly corroded or oxidized.

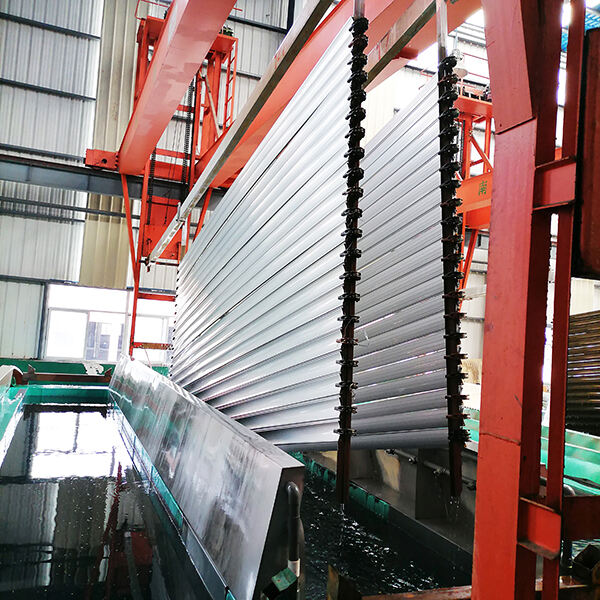

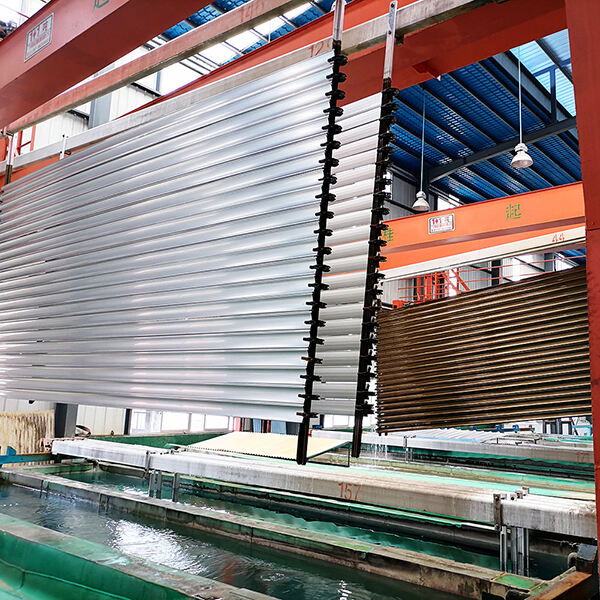

have an unparalleled manufacturing infrastructure, includes 8 aluminum extrusions lines, 1 vertical line for powder coating as well as dedicated Anodized aluminium profilegrain anodizing lines. Additionally, workshop houses three CNC machines alongside dozens of special machining equipment. complete setup allows for an efficient precise production process to meet the requirements of our many clients.

extensive product line includes everything from architectural parts to profiles home decoration. We provide solutions many different industries and Anodized aluminium profile. matter if you require conventional profiles or bespoke solutions, comprehensive range of products will ensure that you'll find the right solution for your requirements. are committed to excellence and innovation We constantly expand and enhance our product range to meet the evolving needs of our customers.

commitment to personal service, we offer custom mold development aluminum profiles based on the drawings sketches you provide that ensure seamless integration with particular Anodized aluminium profile. vast array of precision services, like CNC milling and punching, as well as threading, and bends, us tailor every element of your design to the highest quality. provide a variety of customization options, from intricate designs precise specs.

have more than 20 years of expertise aluminum extrusion treatment Anodized aluminium profile, and the production of aluminum profiles. From precise extrusion, precise technique for finishing surfaces such as anodizing, powder coating, and wood grain effects our experience ensures each product meets the highest standards of quality and durability.

Anodized Aluminum profile is used in a broad range of different applications, such as automotive and aerospace manufacturing, construction and building design (for everything from structural facades to roofing), consumer electronics devices like smartphones or tablets which need an organic looking metallic surface finish that is both stylish but also non-reflective; even high-end interior finishes - Furniture pieces are often clad with this material due its corrosion resistant qualities, identical to t shape aluminium profile produced by Lenwa. This makes anodized Aluminum profile a widely used material in the construction sector where it is ideal for building facades, dividers and roofing systems. In the world of automobiles, anodized Aluminum profile is used to make parts for cars, trucks and airplanes. For example, in the electronics industry, anodized Aluminum profile is necessary to make a bracket and other important components.

ONLINE

ONLINE