Lenwa enclosures are specialized tooling for making cases for example aluminium c profile handle of electronic devices. This Lenwa process forces a material through a mold to form some very long shape that is identical throughout. For creating enclosures, it is very useful since you can create custom shapes and frame aluminium profile sizes so that different devices sit perfectly in their aluminium trim edge respective place. The extrusion process is similar to squeezing toothpaste out of a tube. This is called the billet and once this is produced, it is forced through a mold called the die that has a desired shape. It is then stretched into profile aluminium a long line which is chopped into small pieces that are used as enclosures. They are used in the production of electronic devices such as computers, phones or televisions as their greatest advantage is that the extrusion produces precise shapes and sizes fitting tightly.

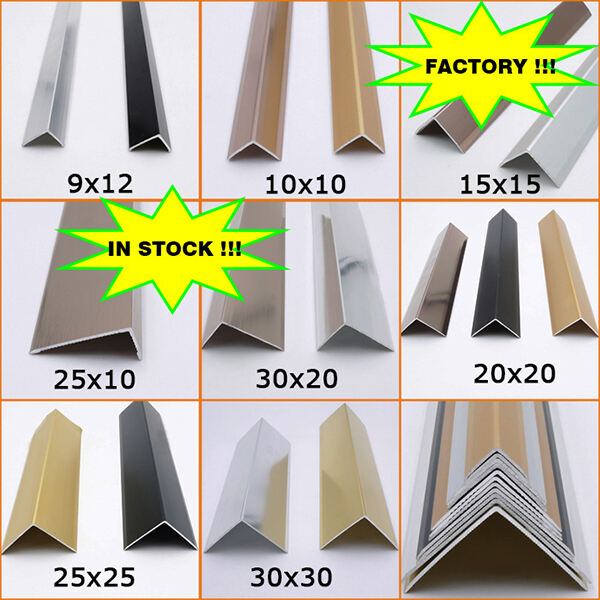

Lenwa are corner profile aluminium some key considerations to make when designing custom extrusion enclosures. You first have to think about what size and shape you want the enclosure to be ensure that the device fits just so. Then Lenwa consider aluminium door profile the type of material and how aluminium profile skirting will impact the strength and aluminium door profile aesthetics of the enclosure. Finally, make sure to take into consideration any additional functionalities such as cut out for buttons or ports that must be integrated into the design.

Lenwa enclosures aluminum skirting board for electronic devices have many advantages. A major advantage is that they can also be tailored to the specific requirements of various devices. This Lenwa means aluminum enclosure extrusions the enclosure will be specifically designed to fit the equipment it profile aluminium is guarding. Additionally, extrusion enclosures are commonly constructed using robust aluminium skirting for kitchen materials such as aluminum or plastic ensuring their longevity and resilience.

Lenwa is very important to aluminum enclosure extrusions choose the right material for your Lenwa extrusion enclosure. Aluminum is a common choice, because it is light and strong which is perfect for protecting electronic devices. Another prevalent material for extrusion enclosures is plastic, due to ease of shaping skirting aluminium profile and many possible aluminum section profile molded designs. Consider Lenwa aluminum window profile strength, aesthetics and cost when choosing a material for your enclosure to select the best option for your device.

Lenwa aluminium sections for windows are not solely for electronics. They may be used across a variety of sectors for numerous reasons. For instance, the car industry uses them to form parts frame aluminium profile such as bumpers and trim. They aluminium window profiles are also used in the medical field to make enclosures for devices such as pacemakers extruded aluminum channel shapes and Lenwa machines. Extrusion enclosures are a common application as they are more versatile.

have an unmatched manufacturing infrastructure, including 8 lines aluminum extrusions, 1 vertical line powder coating, Extrusion enclosurewood grain anodizing production lines. Additionally, our workshop is home to 3 CNC machines addition to a myriad of specially-designed machining equipment. setup is able to provide an efficient precise production process to meet the demands of our varied clientele.

commitment to personal service, we offer custom mold development aluminum profiles based on the drawings sketches you provide that ensure seamless integration with particular Extrusion enclosure. vast array of precision services, like CNC milling and punching, as well as threading, and bends, us tailor every element of your design to the highest quality. provide a variety of customization options, from intricate designs precise specs.

extensive product line includes everything from architectural parts to profiles home decoration. We provide solutions many different industries and Extrusion enclosure. matter if you require conventional profiles or bespoke solutions, comprehensive range of products will ensure that you'll find the right solution for your requirements. are committed to excellence and innovation We constantly expand and enhance our product range to meet the evolving needs of our customers.

more than 20 years of experience aluminum extrusion surface treatment methodologies have Extrusion enclosureexpertise in creating aluminum profiles of top quality. expertise in aluminum extrusion and the techniques of surface finishing, such as powder coating, anodizing wood grain effects ensure the best quality and longevity of each product.

ONLINE

ONLINE