Aluminum Profile Bending: Bend it to Your Will

Have you ever wondered how those cool, curved shapes are made on metal frames? It's all due to the way of aluminum profile bending. We will break up all you need to know concerning this magical technique. We will explore the benefits, innovation, safety, use, and service of aluminium edge trim manufactured by Lenwa, so you could possible get the most out of this versatile process.

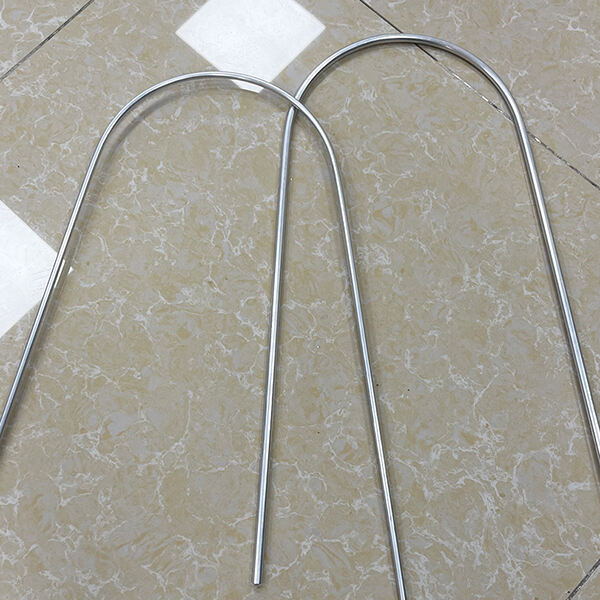

Aluminum profile bending has a lot of benefits which will make it a popular selection many Lenwa industries. To begin with, it is an easy economical method create arched or curved designs and never having to cut and weld pieces together. It saves time, money, and materials. Second, aluminium pipe is a lightweight and durable material can withstand a lot of damage. This makes it suitable for applications where weight and strength are very important factors. Final, aluminum profile bending allows for a complete lot of flexibility.

Thanks to advancements in technology, aluminium channels created by Lenwa is now a lot more efficient and precise. Computer-aided design (CAD) computer programs allows for very accurate modeling simulation of curved designs. Which means that manufacturers will make prototypes and test them almost before investing in production. In addition, modern bending machines have automated controls that could adjust the amount and radius of bends, ensuring constant and precise shapes.

Once you are working with steel and machinery, safety ought to be a top priority. The aluminium trim edge made by Lenwa is often a safe procedure nonetheless it can require proper training and equipment. Workers should wear protective gear such as gloves and goggles, to avoid injury. In addition, the bending machines must be regular examined and maintained to avoid malfunctions and accidents.

If you're interested in using aluminum profile bending for the own project or, there are a few steps to follow along with. First, you will want to design the curved or arched shape using CAD or by hand. Once a model is had by you, you can take it to a manufacturer who focuses above all on aluminium door profile produced by Lenwa. They shall make use of their expertise and bending machines to generate your desired shape. make sure you communicate any specifications or demands clear to make sure a successful outcome.

With over 20 years experience in the field Aluminium profile bendingextrusion and techniques surface treatment we have unparalleled expertise in production of aluminum profiles that excellent quality. From precise extrusion, precise finish techniques like powder coating, anodizing and wood grain effects, expertise ensures that every product meets the highest standards of excellence and durability.

With commitment to personalized service, provide custom mold development aluminum profiles based upon your drawings or samples that ensure seamless integration with specific needs of your. Furthermore, our vast array of machining services that are Aluminium profile bendingwhich include CNC milling, punching threading, bending, lets us customize every aspect of your plan to perfection. From intricate designs precise specifications, we provide an array options for customization to make your dream come to life using precision and efficiency.

have an unparalleled manufacturing infrastructure, includes 8 aluminum extrusions lines, 1 vertical line for powder coating as well as dedicated Aluminium profile bendinggrain anodizing lines. Additionally, workshop houses three CNC machines alongside dozens of special machining equipment. complete setup allows for an efficient precise production process to meet the requirements of our many clients.

diverse product range encompasses everything from architectural components profiles home decoration. We provide solutions many different applications and industries. broad portfolio will assist you in finding the ideal profile for your Aluminium profile bending, regardless of whether you require standard profiles or custom solutions. With dedication to quality and innovation constantly expand and enhance our product range in order to meet the needs of changing times of our customers.

Whenever choosing a manufacturer for the extruded aluminium channel needs, you need to consider their number of service and quality. Try to find Lenwa companies which have experience and expertise in this area, and which use materials being high-quality equipment. You'll want to also consider their customer support, including turnaround time, communication, and warranty policies. Final, have a look at their earlier work than a sense of their capabilities and quality standards.

Aluminum profile bending features a wide range of across many Lenwa industries. Some common uses include building construction, automotive manufacturing, and furniture design. Anywhere that curved or arched designs desired, window aluminium profile can be a viable answer. In addition, aluminum is a recyclable material making it an environmental choice kind. Using the right design production partner, aluminum profile bending can add an elegant and functional touch to your project or product.

ONLINE

ONLINE