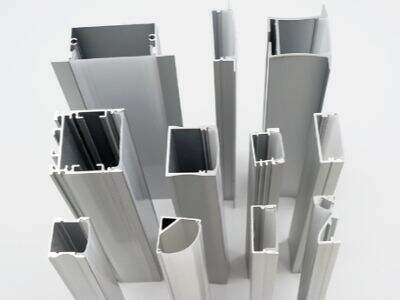

Selecting the correct finish for custom aluminum extrusions is critical. At Lenwa, we understand the fact that the finishing can ultimately affect how your aluminum will appear and work. A decent finish helps protect the aluminum and affects how long it will last. Whether you want a shiny look or rough feel, there are plenty of options to consider. All types of finishes have something to offer, and knowing what those are can help you make an intelligent decision for your next project. So, how should you be thinking about the finish of your aluminum products

What Does Finish Do to the Longevity of Custom Aluminum Extrusions

Finishing is about more than just looks. It’s also essential for maintaining aluminum for a long-lasting payback. Various finishes — grinding, sanding or bead blasting along with anodizing or powder coating — provide the aluminum different degrees of protection. For one thing, anodizing adds a special layer that is very hard and leaves the metal difficult to scratch and corrode. People are fans of this finish because the aluminum is protected against some wear and tear. Powder coating, on the other hand, provides a vibrant appearance and shield against moisture and ultraviolet radiation from the sun. Those finishes may not be good enough, and the fabric could chip or fade soon after, costing you more in repairs. Consider a car: with high-quality paint, it will last longer and look better. The same can be said for aluminum. Another consideration is that the some of finishes are going to make the aluminum harder. This is incredibly handy for when the aluminum must hold a heavy load or take ultrahigh impacts. When you choose the proper finish, you are not only selecting a color but a longevity for your aluminum extrusions

What to Think About When Choosing a Finish for Your Aluminum Extrusions

When choosing your surface, think about where as well as exactly how you strategy towards utilize your light weight aluminum. Inquire on your own concerns like: Will certainly it view a great deal of the outdoors? Will certainly it remain in a damp atmosphere, beside sprinkle? Nobody kind of surface will certainly help every circumstance. Likewise consider exactly how you desire it towards seem. As well as luster can easily include a contemporary, cleanse appearance whereas matte may be the appropriate suit on one thing much a lot extra durable or even normally influenced. Different surfaces likewise react to cleansing as well as upkeep in a different way. If you perform require one thing that is simple towards cleanse, that is an essential one. You might likewise think about the cost. Some might expense much a lot extra at first, however in time might conserve you cash in upkeep. Constantly consider exactly just what the light weight aluminum will certainly be actually utilized for in the long run. For a structure, you might desire a much more resilient surface that can easily endure survive use, for instance. Our team can easily direct your options at Lenwa. Selecting the appropriate surface is actually essential for making the most of the prospective of your light weight aluminum items. Do not remain in a thrill as well as contrast to ensure that you have the ability to opt for exactly just what fits you finest

There are some common issues that people might encounter when selecting finishes for aluminum extrusions

Well for one of the most common things such as peeling, or flaking paint. This occurs when the surface is not cleaned properly before a finish is applied. Also, if the aluminum has dirt, oils or any sort of material on it, the finish may not adhere well. Another issue is color fading. Sometimes the finish is also non-weather-resistant or not sunlight friendly. When the color wears off, aluminum can take on an old, drab appearance despite being quite new

Rust and corrosion are also an issue, particularly when the aluminum extrusions are used outdoors

Aluminum does not rust as iron does, but it can oxidize. Inferior coatings can also let moisture get to the metal, and degrade slowly. It can also be an issue with getting scratches. A scratched finish can be worn away to raw aluminum underneath, which corrodes faster. Last but not least, sometimes finishes can appear different depending on how they are executed. Finishes, for instance, may look lovely on a small sample but not match in color or texture when applied to large pieces. These prevalent finishing problems are things to take into account when selecting the finish for your architectural aluminum extrusion

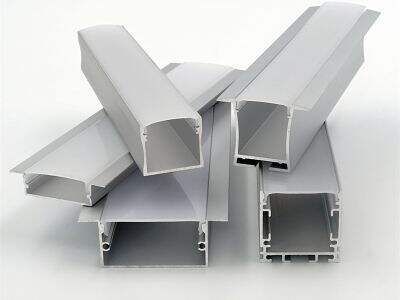

Some other custom aluminum extrusions with good finishes are provided, so if you need excellent quality then Lenwa is an option worth considering. At Lenwa, we offer wholesale custom aluminum extrusions in a range finishes, from brushed to anodized or powder-coated. All of them provide serious weather protection and good looks. If you choose Lenwa to be your supplier of aluminum, Your satisfaction is guaranteed on our top quality. Be sure to ask about the finishing techniques they employ. Each method offers different benefits. For one, powder coating provides a thicker and more durable finish that won’t chip or scratch as easily

You can also ask how long they finishes that are provided will last. Lenwa has a passion in supplying materials that are durable enough for architectural applications subjected to rough weather. Finishes You can also select from different colours and textures at Lenwa. That's right, you can coordinate the aluminum with your architectural details. Be sure that they will have samples of the finishes, and you can see what quality is like and how it looks on bigger pieces. By working with Lenwa’s team you’ll be able to speak directly to the experts who can make sense of everything available and explain how it relates to your project

When considering finishing options for non-residential applications, you’ll want to consider both aesthetics and performance

First, decide the look that you want. Or would you like a shiny, loud look, or something matte and understated? In architecture, the looks also matter to a great extent as these should match up with the structure. Consider, secondly, where the aluminum will find itself. So if you’re going to have it out in heavy rains or intense sun, you need a finish that can take them. This is where you need to ask about longevity and maintenance. Pick a finish that needs minimal upkeep through the years to help ensure that the aluminum remains looking fresh longer

Yet another factor to think about is the safety of the finishes. Some finishes may not be appropriate in places where people will touch the aluminum often, but others could be more robust and less likely to show wear. And consider the environmental toll of the finishes, too. Some are more environmentally friendly than others – you could always chat to Lenwa about eco-friendly options. Lastly, ensure that you select a finish for whichever material you choose to use that falls within your budget. Some finishes might cost more, but they may save you money down the road if they last longer. By carefully considering these elements and collaborating with Lenwa, you can determine the best finish options for your custom aluminum extrusions that add value to both the aesthetics and functionality of your architectural designs

Table of Contents

- What Does Finish Do to the Longevity of Custom Aluminum Extrusions

- What to Think About When Choosing a Finish for Your Aluminum Extrusions

- There are some common issues that people might encounter when selecting finishes for aluminum extrusions

- Rust and corrosion are also an issue, particularly when the aluminum extrusions are used outdoors

- When considering finishing options for non-residential applications, you’ll want to consider both aesthetics and performance

EN

EN

ONLINE

ONLINE