Though companies such as Lenwa are already looking for ways to save money in the manufacture of their aluminium sections.

Introduction

An efficient design can help to reduce tooling costs in custom aluminum extrusions. It pays to get a head start by putting all your ideas down and thinking about what you really need. Instead of needing lots of changes later (with associated cost), try to make your design as clear as possible from the beginning.

About us

For searches for those who have been seeking cost effective tooling for custom aluminum extrusions can seem a bit like treasure hunting sometimes, however that's just what you need. But there are good choices out there, with a little bit of doing your homework and backing them.

Benefits

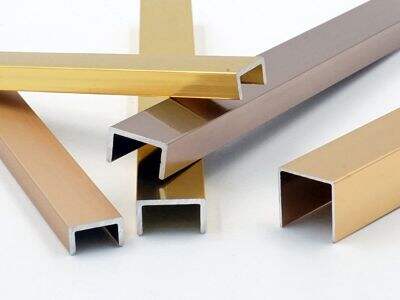

If you are engaging in a custom aluminum extrusion project, there is no doubt that you want to keep costs as low as possible. The alu u channel are several ideas to help you reduce these costs and plan well for your project. First, think about your design. A simple pattern tends to cost less than a complex one. If you can, simplify your design as much as possible.

Innovation

A number of variables may effect tool costs when it comes to aluminum extrusions. First, the design you select really matters. Elaborate tooling is required for intricate design-work and this can be costly. Those of you who are uncertain can turn to experts like aluminum angle trim Lenwa, who will simplify your design without sacrificing quality.

Conclusion

There's no substitute for experience when it comes to knowing how to save money on your next aluminum extrusion project. A good place to start is online. You can find a aluminium door profile lot of sites and forums that talk about how you can save money when it comes to manufacturing, and aluminum extrusions are no exception.

EN

EN

ONLINE

ONLINE