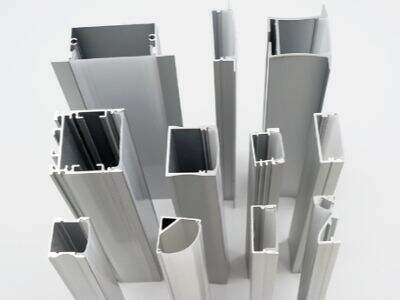

Designing parts using a method called extrusion by working directly with manufacturers can also be important. We at Lenwa can attest to this ourselves. When we work in tight cooperation with the company that makes our products, everybody wins. We brainstorm to develop better designs and refine quality, so that what our customers have in mind aligns with the finished product. By collaborating, we can also make the entire process faster and more readily adjust to any new changes in the design, which is incredibly crucial aligning with today’s fast paced world. It’s really all about communication between the designer and manufacturer. This collaboration yield extrusions both functional and innovative

What are the main advantages of working directly with a manufacturer on the design of your extrusion

So when designers collaborate directly with manufacturers as Lenwa, good things happen. For one, it’s quick to solve problems. Should a designer encounter a problem with the design, they can immediately speak with the manufacturer. They can talk on a call or in person, instead of exchanging emails. This fast form of communication allows them to nip problems in the bud. Second, it ensures improved quality control. When the designer works with the manufacturer from the outset, they can witness how design changes during production. That means they can react on the fly if something looks wrong. If, for example, a piece of equipment is breaking while in extrusion, the designer can see why it’s happening and change the design with the manufacturer. This partnership is also helpful in wastage prevention. Such errors early in the process can result in wasted materials. But if a designer, and the company that does the manufacturing, work closely together, they can avoid these mistakes, making everybody more efficient. And, last but not least—clients are happy when they see a product that answers their needs. When Lenwa partners with manufacturers it has a good track record of getting the products that are released right, and giving customers what they want

Extrusion Products: How Direct Collaboration Delivers Better Customization

Customization is essential in today’s business landscape, and when it comes to extrusion products, no area is more important. By collaborating directly we are able to get full input on our customer needs, which helps it makes easier for Lenwa to provide tailored solutions. When there’s open communication we’re able to take input from the customer and immediately turn that around to our manufacturing team. It gives us insights into what kind of features or looks and feels clients are keen on, which can differ dramatically from project to project. For example, a customer wants a unique shape for their extruded plastic – our partnership enables us to work together on new design elements and advise on material selection & production capabilities at the same time. We can rapidly prototype and tailor samples on the fly, instead of waiting for weeks. This collaboration allows for faster turnaround times on custom orders. And it offers us an opportunity to make products that really stand out in the market. And when clients visit our factory and see how fast we can retool, and customize products just for them, it strengthens their trust in Lenwa. Because customers like the feeling of getting something custom, not one-size-fits all. So dealing directly with the makers actually increases not just the quality of products I get from them, but also makes for better and faster custom work. This collaboration and communication is to the benefit of Lenwa growing mutually with our clients

How Direct Manufacturer Relationships Result in Better Quality and Performance products

When businesses engage directly with manufacturers like Lenwa, they tend to get higher quality, and therefore better performing products. This occurs because the company has a strong relation with the manufacturer. Companies that work directly with manufacturers can speak freely about their needs and expectations. For example, if a company is looking to produce a new part using extrusion, it can bring its ideas directly to the experts at Lenwa. This way, both sides know what is feasible and what isn’t

Often, when businesses talk through third parties, information can be mis-communicated or confounded. This can result in errors in the produced products. But working directly with Lenwa, companies can receive data that is on the mark and adjust quickly. So that means better designs and fewer mistakes. In addition, team Lenwa is up to date with the latest technologies and developments in extrusion design. They can offer valuable insights to make the product better still. This partnership helps ensure the finished products are quality-made and work well, exactly as customers need them to

Also, in cooperation with Lenwa it is possible to test and improve the platform in real time. If something is problematic, or if there's a change that the person wants to make, you can attend to it quickly. For instance, if a prototype requires any modifications to buttress its strength, the team also can collaborate on incorporating those changes. This direct link leads to a more rapidly generated design and better end product. In general, when companies like Lenwa and its partners collaborate directly, the result is something that’s more robust and reliable for customers

How You Can Simplify Your Supply Chain by Working with Extrusion Manufacturers

For companies, to collaborate with extrusion manufacturers such as Lenwa can reduce the supply chain significantly. A more efficient supply chain is one in which products are both made and delivered in an efficient manner — saving time and money. By getting more involved with extruders, companies can reduce the number of linkages in their supply chain. Typically, when a company wants to purchase a product, it might request bids from several different suppliers and transportation services. But when you work directly with Lenwa, everything is so much easier

One reason that happens is a result of better planning. Lenwa works with companies to help them determine the best ways to produce their goods. Because he is involved from the get-go, Lenwa can counsel on which materials, designs and production methods are likely to work best. This can save time and money. Companies can get their parts made faster and with fewer errors — meaning less time fixing issues later on. What’s more, when you have a well-trusted manufacturer like Lenwa, the risk of delays is minimized. If companies can count on Lenwa to provide the materials they need when they need them, they can forecast their production schedules more effectively

Another key point: Lenwa can provide this product with bulk pricing, while offering organizations that connect with them directly even better deals. That’s good news for businesses, which can save money by ordering more inventory. Less expense being less sacked for and charges lower down to give the consumer a better price. In the end, by working with Lenwa, enterprises are able to develop an optimized, cost-effective supply chain. Such collaboration also facilitates a more rapid production and delivery, to the overall benefit of all involved

Top Trends in Extrusion Design for Wholesale Buyers – The What, When & Why

Here's why wholesale will need to take notice of the latest advancements in extrusion design if they hope to remain competitive. One major trend is the rise of customized products. Buyers want unique designs that fit their particular needs. Companies like Lenwa are able to produce completely unique extrusions that are tailored for exactly what wholesale buyers desire. This provides businesses with the opportunity to provide their customers something unique that is unlike anything else in the marketplace

Another style is the eco-friendly type. A lot of buyers are more environmentally conscious, and they want to make shopping decisions that reduce waste and harm to the planet. The material used is 100% recycled (polystyrene, polycarbonate) oblique, and positioned raw materials for the threaded extrusion. This not only benefits the environment, it also brings in customers that like to do business with companies whose presence has a positive impact on the world. Wholesale buyers who choose to work with responsible manufacturers have the opportunity to ensure that their products reflect the values of their consumers

The increase usage of advanced technology is another influence in the evolution of the design for extrusion. New technologies like 3-D printing are increasingly popular, which means it is easier for manufacturers to design complex shapes and designs. Lenwa keeps up on such technology so that they can assist buyers in new advances. This can result in improved products that do more. By paying attention to these trends, wholesale buyers can make decisions that improve their product offerings and allow them to remain relevant in the marketplace. In this constantly changing market, the more a buyer knows about recent advancements in extrusion design, the better off they will be when making business decisions

Table of Contents

- What are the main advantages of working directly with a manufacturer on the design of your extrusion

- Extrusion Products: How Direct Collaboration Delivers Better Customization

- How Direct Manufacturer Relationships Result in Better Quality and Performance products

- How You Can Simplify Your Supply Chain by Working with Extrusion Manufacturers

- Top Trends in Extrusion Design for Wholesale Buyers – The What, When & Why

EN

EN

ONLINE

ONLINE