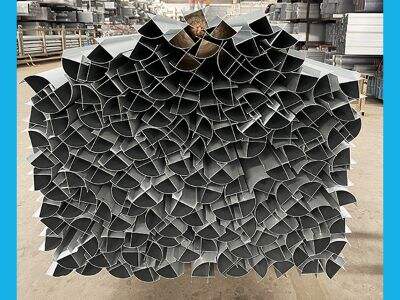

We designed this enclosure to have the right kind of extrusion for the job!

Extrusions are components assisting in the formation of the enclosure that can be created of various materials. At Lenwa, we have a wealth of experience in producing the right extrusions for your project. We’ll explain various kinds, what to look for, and how to steer clear of common pitfalls. So, let’s get started on how you can choose the best extrusion for you!

Types of Extrusions Explained

There are a variety of extrusions and they each serve their own, special purpose. Some extrusions work wonders for sturdy frames, others for intricate designs. Aluminum is a preferred material: It is light and sturdy. However, there are also plastic and aluminum channel extrusions. Knowing what each can do will help you choose the best one for your project.

3 Things to Factor When Choosing an Extrusion for Your Enclosure

Consider the size and shape of your enclosure when choosing an aluminum corner extrusion. You also have to think about how much weight it should be bearing. If you are doing something outside, you have to make sure the material can tolerate weather. Also, consider what its assembly is like. Some are easier to use than others.

How to Fit Extrusion to Perfection and Tips to Make It Happen

Fit is super crucial when it comes to nailing the look. You need to ensure everything lines up and fits snugly. One trick is to measure twice, when you’re cutting, and before. Another suggestion: if you’re cutting pieces, use some sort of a template or a guide. This can help ensure all of your pieces are of the proper size and shape.

Choosing a Material for your Custom Enclosure Extrusion

It really can make a difference the materials you choose. Each material — aluminum, plastic, steel — has its advantages. Aluminum, for example, is excellent for both indoor and outdoor projects because it doesn’t rust. Plastic could be the answer if you find you’re after something lightweight. Steel is super strong and great for heavy-duty enclosures.

The fact that would one day be a part of the project that just couldn’t be extruded should not be one’s motivations to learn more about extrusion process and improve upon how one manages his or her business, staffing and force the extrusion application! allow us to explain! types of aluminum extrusion there are two main types of aluminum extrusion that we, that’s Jan and Jeff, want to show you that don’t work, are extremely costly and compromise your entire project, or production. All too often these days, we see amazing and excited teams working on their great framing extrusion projects. The team proudly brings it to their production manager and finds out that the project is great, but just can’t be extruded.

One big mistake is that there’s no plan in advance

What you have to know is exactly what you desire before you get started. Another error is to not think through all of the options. Sometimes the best fit for your project is not the most direct. It’s also easy to forget that the material will respond differently to diverse environments. Remember that your accessory will be used somewhere.

In conclusion, the extrusion you choose for your custom enclosure is a big deal. By knowing the different breeds, weighing the characteristics and dodging common mistakes, you can more confidently ensure that the one you choose is the best option for your project. Just don’t forget at Lenwa, we’re with you every step of the way!

Table of Contents

- We designed this enclosure to have the right kind of extrusion for the job!

- Types of Extrusions Explained

- 3 Things to Factor When Choosing an Extrusion for Your Enclosure

- How to Fit Extrusion to Perfection and Tips to Make It Happen

- Choosing a Material for your Custom Enclosure Extrusion

- One big mistake is that there’s no plan in advance

EN

EN

ONLINE

ONLINE