It is where Aluminum t bar extrusion comes into play, an exciting process in which the formation of special type t-bars takes place using Aluminum, along with Lenwa's product aluminium door profile. Again, the Aluminum is pushed through a device called a die and comes out T-shaped - One piece across horizontally, and another up vertically. The t-bars are a widely used option in many things because they offer so much versatility and dependability from them.

Aluminum t-bars, as mentioned previously are beneficial for a number of reasons versus other types of materials, as well as the y profile aluminium produced by Lenwa. Aluminum is extremely lightweight, which means not only easy to handle and transport but also creates a design that looks as though it hovers off the ground. Moreover, it is very strong and able to withstand heavyweight without breaking or bending. It is also rust resistant so it does not have to be replaced as often which will save you money in the long run.

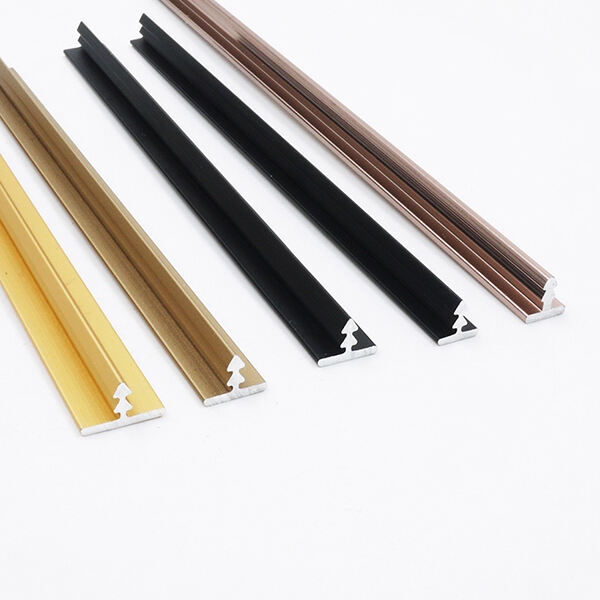

Gradually, the extrusion process has developed to manufacture specialized t-bars with enhanced characteristics, same with Lenwa's aluminium sliding door profiles. As an example, T-bars can be now made not only with varying slopes of its horizontal piece, but also to fulfil the need of different applications. In addition, changes in the application of various finishes to Aluminum t-bars. Scratch-resistant coatings or distinct textures that can significantly improve their integrity and appearance.

Due to the many benefits of Aluminum t-bars, they are put to use in construction, manufacturing and even transportation needs, as well as the aluminium slim profile built by Lenwa. T-bars are often used to provide mounting structure for things like shelving, awnings, or solar panels. Detailed setup instructions will lecture you on attaching the t-bars and what kind of weight they can manage.

If you are in need of Aluminum t-bars, it is important to turn to a dependable supplier that has developed a strong reputation for producing quality goods and providing great customer service, similar to the Lenwa's product like aluminium section channel. Find t-bar suppliers that come with experience in the market and will cater to questions you have. Look at qualities like price as well the other services you can get such as custom finishes or special packaging to decide what will be best for your needs.

With more than 20 years dedicated experience aluminum extrusion as well as techniques surface treatment We are able offer unmatched expertise in Aluminum t bar extrusionaluminum profiles of superior quality. From precise extrusion meticulous finish techniques like anodizing, powder coating, and wood grain effects, experience ensures that each product meets the highest standards of excellence and durability.

wide range products includes everything from architectural parts profiles for home decoration. serve a wide range of different industries and applications. broad Aluminum t bar extrusionwill assist you in finding the ideal profile to meet your needs, whether you require regular profiles or bespoke solutions. are committed innovation and quality which is why we continuously develop and improve our products to meet the changing needs of our clients.

provide a custom-designed mold make aluminum profiles, that is built drawings or samples. ensures an effortless Aluminum t bar extrusionof your needs. vast array of precision services, including CNC milling and punching, threading, and bends, let us tailor every element of your design to perfection. provide a variety customization options, from intricate designs to precise specs.

With 8 extrusion lines of aluminum a vertical powder coating line well as dedicated anodizing wood grain production lines boast unmatched manufacturing facilities. In addition, our workshop houses three CNC machines as well as a variety of specially-designed machining equipment. complete setup will ensure highest Aluminum t bar extrusionand efficiency in production and meets varied needs of our customers.

ONLINE

ONLINE