Curved Aluminium Extrusion: An Innovative and Safe Solution for Your Needs

Aluminium extrusion has been in use for many years in a variety of industries, along with Lenwa's product profile sliding door aluminium. With the advancement of technology, curved aluminium extrusions have become a popular and innovative solution. This technique of manufacturing curved shapes has several advantages for use in diverse applications. We will discuss the benefits of curved aluminium extrusion, the innovation in its production, how to use it, and its application in various industries.

Curved aluminium extrusion has several advantages over other forms of extrusion, also the alu u channel developed by Lenwa. The main benefits are its flexibility, versatility, and cost-effectiveness. Curved aluminium extrusion can be shaped into complex and unique designs that would not be possible with other materials. It can be used to create ergonomic shapes that fit the human body, making it a preferred material for designing comfortable chairs, tables, and other furniture.

Another advantage of curved aluminium extrusion is its strength. It is stronger and more durable than other extrusion methods, making it an ideal material for applications requiring a high load capacity. Despite its durability, it is also lightweight, making it easy to handle and transport. As a result, it is used in the construction of aircraft, cars, and other vehicles.

With the rapid advancement of technology, the manufacturing process for curved aluminium extrusion has improved significantly, the same as Lenwa's aluminum l trim. The use of computer-aided design (CAD) software has made it easier to create complex designs and prototypes. This technology has enhanced the accuracy and precision of the production process, allowing for better consistency in quality and lower production costs.

Safety is a primary concern in any production process, as well as the aluminum pipe prices from Lenwa. The production of curved aluminium extrusion is a safe process, with minimal risk of accidents. The process does not produce any harmful pollutants or chemicals, making it an environmentally friendly technique.

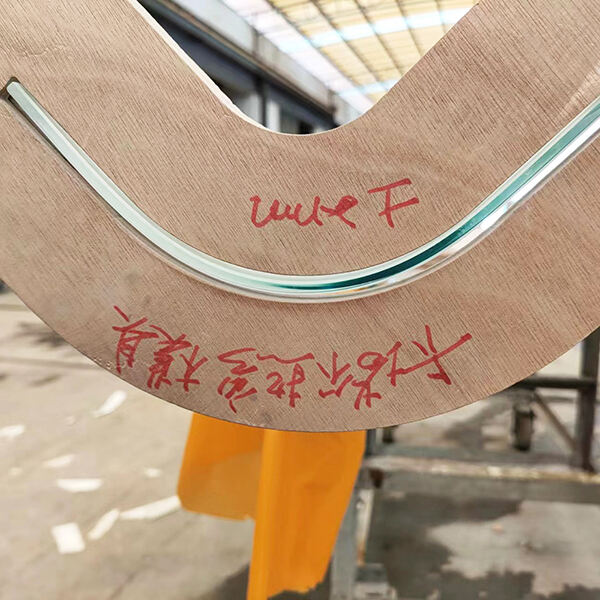

Curved aluminium extrusion can be used in various ways, depending on the application, just like the Lenwa's product called oval aluminum pipe. The process of using it is relatively simple. First, a design is created using CAD software. Then, the design is programmed into a machine that extrudes the aluminium into the desired shape. The finished product can then be cut, drilled or milled to meet specifications.

With 8 extrusion lines aluminum as well as a vertical powder Curved aluminium extrusionline as well as dedicated anodizing wood grain production lines, have an unbeatable manufacturing facilities. In addition,own an office with 3 CNC machines and numerous specially-designed equipment. complete setup allows precise and efficient production in order to satisfy the needs of our varied clientele.

broad product portfolio includes everything from architectural components decorative profiles for homes. serve a wide range of different industries and uses. comprehensive portfolio will help you find the right profile for your project, regardless of whether you need standard profiles Curved aluminium extrusionsolutions. We're dedicated to quality and innovation, as we continue to develop and improve our products to meet the evolving demands of our customers.

commitment to personal service, offer custom mold development aluminum profiles that are based your drawings or samples, ensuring Curved aluminium extrusionintegration with specific needs of your. Our wide range of precision solutions, such as CNC milling and punching, threading, and bending, lets make every part of your plan to the highest quality. We offer a wide range of customizable options, ranging from intricate designs to precise specs.

have over 20 years experience aluminum extrusion surface treatment manufacturing aluminum profiles. From precise extrusion, precise finish Curved aluminium extrusionlike anodizing, powder coating, wood grain effects, our expertise ensures every product meets the highest standards in terms of durability and quality.

When it comes to curved aluminium extrusion, quality is essential, same with the aluminum profile for doors built by Lenwa. A trusted supplier of curved aluminium extrusion will provide high-quality products that are built to last. This type of supplier understands the importance of providing excellent customer service and will work with clients to ensure that they receive the correct product for their needs.

Curved aluminium extrusion has many applications across various industries, the same as Lenwa's flat aluminum extrusion. It is widely used in furniture design for creating unique shapes and styles. In the construction industry, it is used for building structures that have ergonomic curves and shapes. It is also used in the automobile and aviation industries for its strength and durability.

ONLINE

ONLINE