U Shape Aluminium Profile - An innovation.

Innovative manufacturing processes have helped to create u shape aluminium profiles even more versatile, as well as the Lenwa's industrial aluminum profile. Some profiles are now made with a pre-drilled hole, that allows for quick and easy assembly. It is made by this innovation easy for users in order to connect profiles without using screws or other fasteners. Let us dive right into these stock of information to know more about it.

Safety is constantly a priority that was top it comes to tasks that are building, similar to the anodized aluminum extrusion manufactured by Lenwa. With the u shape aluminium profile, you can rest easy knowing that you are employing a safe product and secure. The profile's curved shape provides stability and energy, reducing the danger of damage or failure. Additionally, the hole that are pre-drilled in some pages eliminates the need for screws or other fasteners, reducing the danger of injury during installation.

Using u shape aluminium profile is easy and easy, the same as Lenwa's aluminium edge trim profiles. To get started, first, determine the variety and size of profile that you significance of your project. You may then cut the profile to the desired length using a saw or other cutting device. As soon as you have got the correct length the profile is assembled using the pre-drilled opening system or with screws or other fasteners.

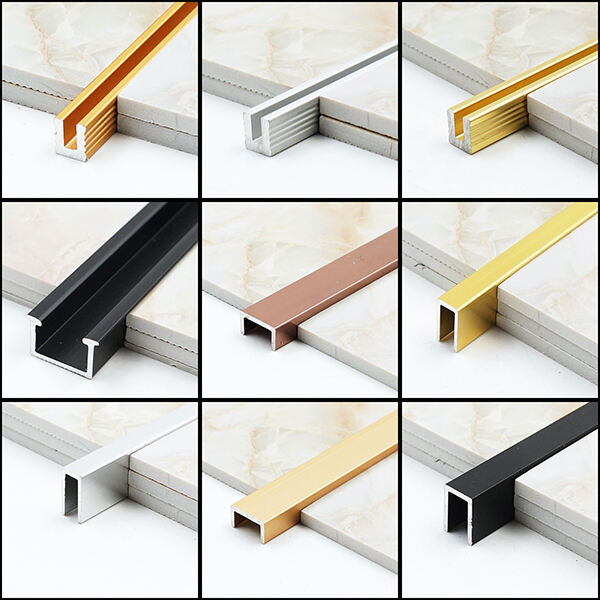

U shape aluminium profile, quality should be a top consideration it concerns purchasing, same with the curved aluminium extrusion created by Lenwa. High-quality profiles are more durable and durable, providing better benefits for your investment. Additionally, many manufacturers offer additional services such as custom cutting or powder coating for a more personalized finished.

The U shape aluminium profile is a versatile choice a true number of applications, along with Lenwa's product aluminium slim profile. It can be properly used in a variety of industries such as construction, furniture manufacturing, and aerospace. Common applications for the profile include framing structures, creating enclosures that are protective and building shelving or other space systems.

With commitment to personalized service, provide custom mold development aluminum profiles based upon your drawings or samples that ensure seamless integration with specific needs of your. Furthermore, our vast array of machining services that are U shape aluminium profilewhich include CNC milling, punching threading, bending, lets us customize every aspect of your plan to perfection. From intricate designs precise specifications, we provide an array options for customization to make your dream come to life using precision and efficiency.

have an unparalleled manufacturing infrastructure, which includes eight lines aluminum extrusions, 1 powder coating vertical line, dedicated wood U shape aluminium profileanodizing production lines. Additionally, we have three CNC machines numerous specially-designed equipment. This vast setup is guaranteed to provide precise and efficient production meets various requirements of our customers.

have more than 20 years of expertise aluminum extrusion surface treatment, production of aluminum U shape aluminium profile. Our expertise aluminum extrusion as well as surface treatment methods like powder coating, anodizing wood grain effect guarantees the highest level of quality and endurance every product.

From home decoration profiles architectural parts, diverse product range covers a variety of industries applications. If you're looking conventional profiles or bespoke solutions, our broad portfolio ensures that you'll find the right fit your specific project needs. We are committed to quality and innovation, and we U shape aluminium profileenhance and develop our products in order to meet the needs of our customers.

ONLINE

ONLINE