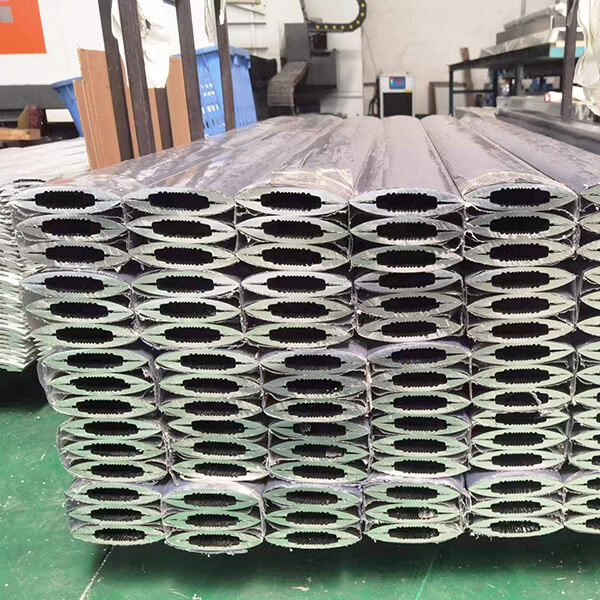

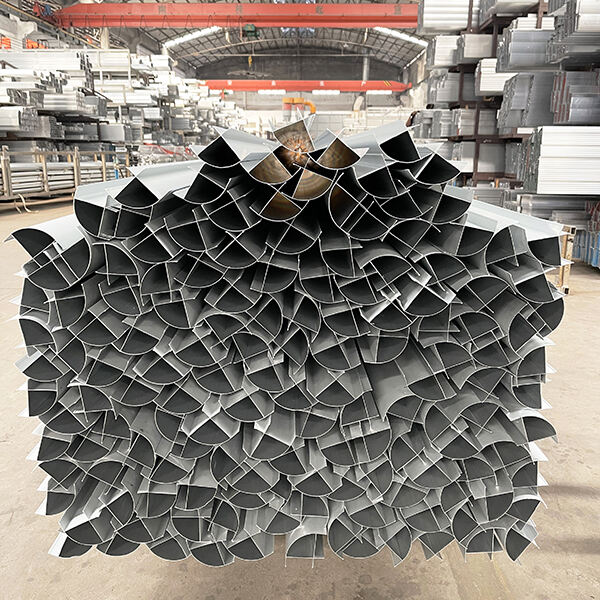

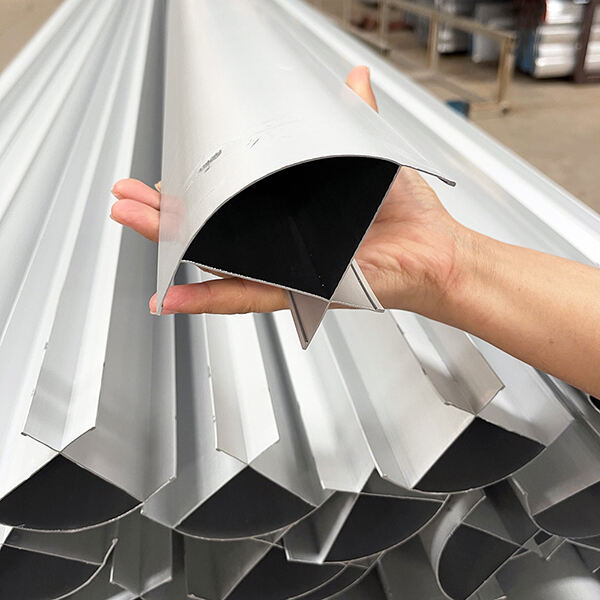

Large aluminum extrusion Large aluminum is created by taking a piece of recycled light weight AL, aluminium billet that has been preheated to over 700 degrees Celsius/1. In this process, aluminum bars are fed cautiously into a hollow chamber and heated to an exact temperature until they are softened enough to be forced through it using pressure applied with the help of a shaped opening known as Die earlier before being cooled off. These steps create aluminum profiles of the highest quality, which will increase their strength while maintaining lightness and durability. It might be used in the construction, transportation or electronics industry - among countless others that you will generate with your list of possibilities.

Large aluminum extrusion Most Versatile Metal - of them All Aluminum is one particular metals, some might argue even the most versatile metal. Its exceptional energy-to-weight ratio is one of the most important benefits. Aluminum used for absorbing light makes aluminum extrusion two strong materials that help make aircraft, high-speed trains and even cars. Another big plus is the resistance to corrosion in aluminum. Because of their resistance to rust and other forms of corrosion, aluminum extrusions are also well-suited for use in outdoor applications.

There have been great advances in the large aluminum extrusion over the past few years. The manufacturing possibilities behind aluminum extrusion is absolutely remarkable when comparing it to standard design and tradition forms of cutting sheets or casting. In addition, new composite alloy recipes have been created with greater resistance and endurance. In a nutshell, these advancements are broadening the reach of aluminum extrusion into an increasing number of applications.

Large Aluminum Extrusion Safety and Practical Applications

Top priorities when working with big aluminum extrusion. In order to operate at their best, it is important be predicated on the instructions from the manufacturer with kindness and use protective equipment such as gloves boots eye wear for your defense and save storage in a dry place away from temperature and moisture. Also, they must be adequately supported and should not experience high-stress or repetitive loading conditions.

When it comes to buying large aluminum extrusion, who you buy from matters just as much of what the product is. If you are in the market to sell your product such as a store bought item of fashion wear, then an aluminum extrusion company with trained professionals experienced over decades can help point out what style and kind of service will provide exactly how much corrosion resistance for selling sake. More importantly, you should most of all select a business that provides good customer service and support - including technical help or post-sales services.

This paired with the versatility of a large aluminum extrusion really helps to make this one product that can be utilized in many different sort's applications:

Manufacturing: Aluminum extrusions are pretty popular in the manufacturing industry to build window frames, roofing and cladding, structural components.

Transportation: Along with the construction of aircraft and high-speed trains, transportation is a considerable user by weight in aluminum extrusions.

Electronics: Aluminum extrusions are used to house electronics and for heat sinks due to the fact that aluminum is an excellent conductor of heat.

Replacement Energy - Aluminum expulsions are utilized in a large number of applications for sustainable and practical power sources including solar panels mounting frameworks, alongside wind turbines parts.

can provide a customized mold for Large aluminum extrusionprofiles made based samples or drawings. This allows seamless integration your requirements. vast array of precision services, such as CNC milling and punching, as well as threading bends, let us customize every aspect of your design to the highest quality. From intricate designs to precise specifications, can provide comprehensive customization options to help you realize your vision using precision and efficiency.

have an unparalleled manufacturing infrastructure, includes 8 aluminum extrusions lines, 1 vertical line for powder coating as well as dedicated Large aluminum extrusiongrain anodizing lines. Additionally, workshop houses three CNC machines alongside dozens of special machining equipment. complete setup allows for an efficient precise production process to meet the requirements of our many clients.

have more than 20 years of expertise aluminum extrusion treatment Large aluminum extrusion, and the production of aluminum profiles. From precise extrusion, precise technique for finishing surfaces such as anodizing, powder coating, and wood grain effects our experience ensures each product meets the highest standards of quality and durability.

wide range products includes everything from architectural parts profiles for home decoration. serve a wide range of different industries and applications. broad Large aluminum extrusionwill assist you in finding the ideal profile to meet your needs, whether you require regular profiles or bespoke solutions. are committed innovation and quality which is why we continuously develop and improve our products to meet the changing needs of our clients.

For some of these large aluminum extrusion, have to be paid attentionwhen following work instruction provided by the manufacture and proper supporting especially PPE(Personal protection equipment). For construction purposes, fastening the extrusions accurately and following safety regulations is critical. If it is done right, large aluminum extrusion is the perfect solution for your project.

ONLINE

ONLINE