1. Uvod u aluminijumske profilne kanale

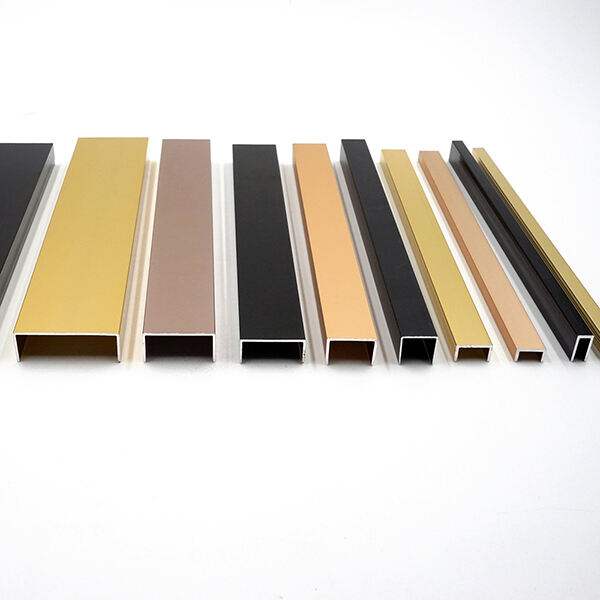

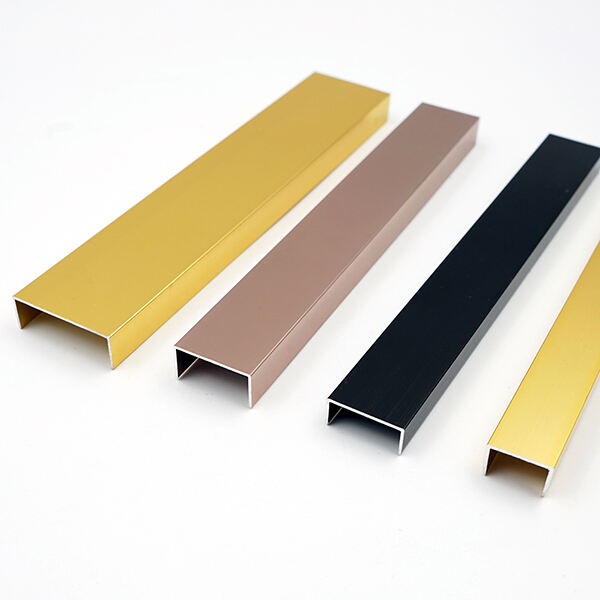

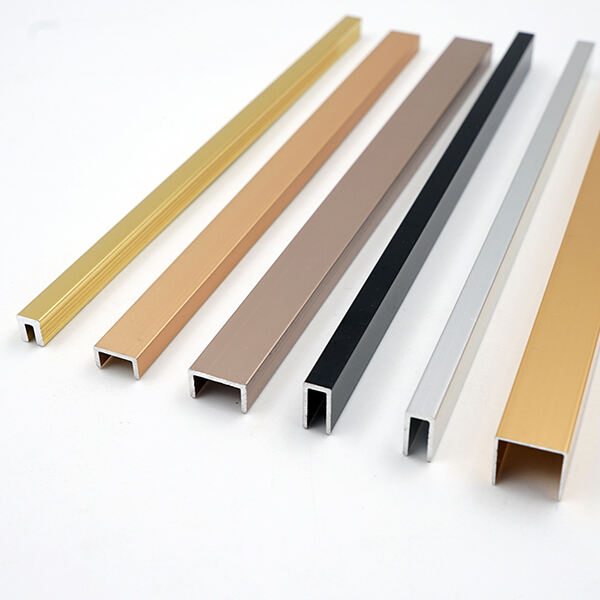

Aluminijumske presjecnice su oblik građevinskog proizvoda koji se upotrebljava za razne primjene, poput građevinarstva, proizvodnje i unutarnjeg dizajna, te su popularni izbor građevinarima zbog svoje trajećnosti, laganoće i dostupne cijene. Ovo aluminijumske kanale se čini od sirovog aluminija kod Lenwa i obrabotava se u različite oblike i veličine, uključujući 'U' oblik presjecnice, 'C' oblik presjecnice i prilagođene profile presjecnice.

Aluminijumske profilne kanale imaju nekoliko prednosti u odnosu na druge građevinske materijale. Prvo, aluminij je laki materijal što ga čini mnogo jednostavnijim za upravljanje tijekom transporta i instalacije. Drugo, aluminij je otporan na koroziju, što znači da se lako ne oksidira, ne korodira ili ne izbledi, što mu pruža dugotrajnu životnu očekivanja. Na kraju, alu u kanal od Lenwa je održiva opcija, stvarno je 100% reciklabilna i može se ponovno koristiti bez gubitka svojstava.

Inovacija je vrlo važna u proizvodnom postupku aluminijumske profilne kanale. Najnovije tehnologije u proizvodnji osiguravaju da aluminijumske izrezivanje kanala od Lenwa imaju povećanu jačinu, trajnost i preciznost kako bi se poboljšala sigurnost. Također, upotreba računalno podržanog dizajna (CAD) i računalno numeričkog CNC upravljanja strojeva pruža preciznije, učinkovitije i konzistentnije proizvodne procese.

Pored toga, sigurnost je ključna razmatranja proizvođača. Aluminijumske profilne kanale čine se vatroodstojnim i neštetnim, što ih čini sigurnim za uporabu u primjenama visokih temperature. Također, proizvodni postupak je strogan, rezultirajući predmetom bez šipki, oštrih rubova i drugih opasnosti za sigurnost.

Aluminijumske profilne kanale imaju širok izbor kroz različite tvrtke. One su pronađene u gradnji, proizvodnji, automobilskoj industriji i unutarnjem dizajnu. Jedna od najčešćih primjena u gradnji gdje se koriste za erekcije, okvire, fasade i druge primjene. U proizvodnji, t kanal od aluminija od Lenwa se koriste za okvire strojeva, prenosne trake i druge industrijske primjene. Također, u automobilsku industriju mogu se koristiti za okvir i dijelove karoserije, te za svrhe unutarnjeg dizajna.

Za osiguravanje optimalne učinkovitosti vrlo je važno znati kako točno koristiti aluminijumske kanale. Za osiguravanje stabilnosti, nosivosti i čvrstoće mora se koristiti odgovarajuća tehnika ugradnje. Osim toga, potrebno je pravilno održavanje i čišćenje kako bi se osigurala zaštita kanala i da ne bude oštećen.

Osim toga, kvalitetna usluga korisnicima je od suštinskog značaja pri kupnji aluminijumskih kanala. pouzdan proizvođač trebao bi pružiti odličnu tehničku podršku, brzu isporuku i odličnu uslugu nakon prodaje. Ova povjerenja osigurava da aluminijevi sekcioni kanali od Lenwa je poslat kupcima' specifikacije i zadovoljava sve zahtjeve. Iskoristiti odličnu uslugu znači da su sve potrebe kupaca ispunjene i da su zadovoljni korištenjem krajnjeg proizvoda.

proizvodnja aluminijumskih profila na temelju skica ili uzoraka. garantuje aluminijumski kanal. Integriranje zahtjeva. Široki raspon preciznih usluga, kao što su CNC freza i udaranje, kao i zavodnja i savijanje, omogućava nam da prilagodimo svaki aspekt vašeg dizajna do savršen

8 linija za ekstrudiranje aluminija zajedno s vertikalnom linijom za premaz praha posvećena je aluminijumskom sekcijom i proizvodnim linijama drvenog zrna. Osim toga, imamo tri CNC stroja i desetine specijalizirane opreme. Postavljanje omogućuje učinkovit i precizan proizvodni proces koji zadovoljava zahtjeve naše raznolike klijente.

široka paleta proizvoda pokriva sve arhitektonski elementi dekorativni profili za aluminijumski kanal. zadovolji mnoge različite industrije i primjene. širok portfolio proizvoda pomoći će vam u pronalaženju idealnog profila za ispunjavanje vaših potreba, bez obzira na to trebate li standardne profile ili prilagođena rješenja. posvećeni kvalitetu

više od 20 godina iskustva u oblasti obrade površine aluminijumske ekstruzije poseduje stručne znanje za stvaranje aluminijumske profilske vrhunskog kvaliteta. Stručno znanje u aluminijumskoj ekstruziji i tehnikama završne obrade površine, kao što su prašno namazivanje, anodiranje, drvećasti efekti osiguravaju najbolju kvalitetu i trajnost svakog proizvoda.

ONLINE

ONLINE