Bevezetés: Az alumínium extrúzió C-szintvonalaként egy olyan fémmagany típusa, amely megbízhatóan használatos számos iparágban. A cikk részletesebben bemutatja az alumínium extrúzió jellemzőit, az iparágban végzett innovációkat, hogyan lehet alkalmazni, valamint a hozzá kapcsolódó folyamatos szolgáltatásokat. A Lenwa c-szintvonalú alumínium extrúzió ellát egy újrahasznosítható és tartós lehetőséget a termékek gyártásakor.

Az alumínium extrúziós folyamat jelentőségét többféleképpen is kimutatjuk. Először is, az alumínium könnyebb súlyú más anyagokhoz képest, ami egyszerűbbé teszi a szállítást, kezelést és telepítést. Emellett korrosziós ellenálló, ami miatt alkalmas információkra és nagyobb kihívásokra vonatkozóan kiválóan használható kívül. alumínium profilcsatorna szintén rugalmas lehet, ami azt jelenti, hogy különböző alakzatokká alakítható, így növeli a tervezések versenyképességét. Ezáltal könnyen testreszabható különféle alkalmazásokra. Az alumínium újrahasznosítható, amiért környezetbarát iparágakban is népszerű.

Az innováció megváltoztatta az alumínium-piacot, különösen az alumínium c csatorna extrúziós gyártásában. A márkák különböző formájú alumínium-extrúziót szerezhetnek különböző gyártási folyamatokon keresztül, például forróextrúzióval, porrétegészel vagy anódzással. A technológia fejlődése lehetővé tette a márkáknak, hogy kisebb, bonyolultabb alakzatokat extrudírjanak, amely növeli a tervek és alkalmazások szélességét. Lenwa csatorna alapú alumíniumextrúziós profilok segít elérni a piaci keresletet minőségi, innovatív és könnyű termékek tekintetében.

A védelem fontos szempont bármely termék gyártásakor, elegendő ok arra, hogy az C csatorna aliumínium extrúzió esetében sem létezik kivétel. A biztonság a gyártással kezdődik és az utolsó terméken végződik. A Lenwa Alumínium nem égető, és ez az információ, hogy nem található tüzelésre, ellentétben más anyagokkal. Ha tűzkiáltós esemény bekövetkezik, az alumínium termékek általában nem hozzájárulnak a tűz terjedéséhez.

Az C csatorna alumínium extrúziók szintén egy sokféle alkalmazásra alkalmasak, amelyek nagyon változtatnak a tulajdonságuk és jellemzőik függvényében. Az alkalmazása iparágakban, mint például a építészet, a védelmi ipar, az autóipar, az elektronika, az építészet és a repülőipar, csak néhány példa. A Lenwa alumínium csatornaextrúziók készülékek gyártására szolgálnak, például keretek, szállító berendezések, kerítések, házi ablakok, ajtok, növényházak, fényoszlopok, partíciók és zárórendszerek között, amelyek elektronikusak is lehetnek mások közt. Az alumínium extrúzió hasznossága azt jelenti, hogy praktikus megoldásokat kínál sok cég számára.

egyedi méretre készített formát biztosítunk az alumínium profilok gyártásához, amelyet a megrendelő rajzai vagy mintái alapján készítünk. Így garantáljuk, hogy a C alakú alumínium extrúzió pontosan megfelel az Ön igényeinek. Széles skálájú pontossági szolgáltatásaink – köztük a CNC marás, lyukasztás, menetkészítés és hajlítás – lehetővé teszik, hogy minden tervezési elemet tökéletesre alakítsunk. Számos testreszabási lehetőséget kínálunk, összetett dizájnoktól kezdve pontos műszaki specifikációkig.

8 darab alumínium extrúziós vonal, valamint egy függőleges porfestési vonal a C-csatornás alumínium extrúzióhoz és a fa mintás felület előállításához – ez egy páratlan gyártási infrastruktúra. Ezen felül három CNC-géppel és tucatnyi specializált berendezéssel rendelkezünk. A beállítás lehetővé teszi egy hatékony és pontos gyártási folyamatot, amely kielégíti sokszínű ügyfeleink igényeit.

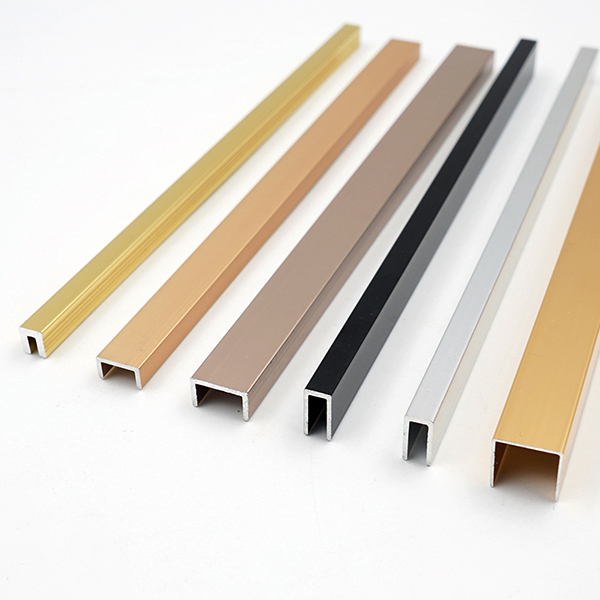

széles termékválasztékunk lefedi az építészeti elemeket és a díszítő profilokat a C-csatornás alumínium extrúzióhoz. Számos különböző iparág és alkalmazási terület igényeit elégíti ki. Kiterjedt termékpalettánk segít Önnek megtalálni az ideális profilt igényei szerint, legyen szó akár szabványos profilokról, akár testre szabott megoldásokról. Minőségre és innovációra vállalkozunk, és folyamatosan fejlesztjük és bővítjük kínálatunkat ügyfeleink igényeinek megfelelésére.

több mint 20 éves tapasztalattal rendelkezünk az alumínium extrúzió, a felületkezelés és az alumínium profilok gyártása területén. Pontos extrúziótól kezdve a C-profilos alumínium extrúzióig, valamint a porcelánfestés, anodizálás és faimitációs felületkezelési technikákban szerzett szakértelem biztosítja, hogy minden termék megfeleljen a legmagasabb minőségi és tartóssági követelményeknek.

A Lenwa csatorna használatához biztosan c extrúzió szükséges, amire egy alumínium extrúziós eszközre lesz szükség. Az alumínium extrúziós eszközök kifejezetten tervezték az alkatrész profilozására hidraulikus vagy stresszel kapcsolatos módon. Az alumínium billet felmelegítésre kerül, hogy könnyedén extrudálni lehessen, amíg olyan hőmérsékletig nem ér el. A fémeket egy meghatározott formájú meghajtó ágyón keresztül hajtják, ami az alumínium csatorna extrúzióját eredményezi és annak c alapú formáját. Az alakítás után sokféle mód van annak megoldására, hogy milyen végleges befejezést alkalmazzanak az extrudált alumíniumra. Ezek között a legnépszerűbb folyamatok közé tartozik az anodizálás, a festés, a porréteg illetve ezek egyes folyamatainak kombinálása mechanikai befejezési folyamatokon keresztül.

A minőség magas szintje biztosan egy aspektus, és alapvetően fontos az alumínium extrúzió csatorna esetében. Az alumínium extrúziókat adott hosszúságokra és pontossági tűrésekhez készítik. A gyártási folyamat során minőségbiztosítási ellenőrzéseket végeznek, hogy biztosítsák a végtermék megfelelését a követelményeknek. A Lenwa technológiával és annak haladottságával, amely ma a piacot vezeti, a minőségbiztosítási ellenőrzéseket gépek segítségével végezik el. extrudált alumínium csatorna azok a cégek, amelyek alumínium extrúzióval foglalkoznak, rendelkeznek általánosan nagyfokú folyamattal, hogy biztosítsák az ügyfelek elégedettségét és bizalmát.

A C-profilos alumínium extrúzió széles körű alkalmazási lehetőségeket kínál. A fémből készült termékek – például acél – gyakran alumínium extrúziós technikával készülnek, mielőtt különféle modern termékekben használnák őket. Az Lenwa alumínium extrúzió könnyűsége miatt széles körben alkalmazzák építőipari, autóipari, légi- és űrkutatási, valamint építészeti alkalmazásokban, további iparágakban is. Az extrudált alumínium sokoldalúsága miatt világszerte egyik legnépszerűbb anyag a gyártók körében.

Online

Online