The Advantages of Aluminum Pipes: Resilience, Security, and Flexibility

Intro

Aluminum pipes have end up being a prominent option for commercial and industrial applications because of their various benefits over various other kinds of pipes. This short post will check out the benefits of Lenwa aluminum pipe, developments in the market, security factors to consider, and the numerous methods they could be utilized.

Aluminum pipes offer several advantages, making them an excellent choice for various construction projects and applications. Firstly, the Lenwa aluminum pipe prices are lightweight and easy to work with, which simplifies installation and reduces transportation costs. Secondly, they are highly resistant to corrosion, making them ideal for outdoor projects and for transporting fluids and gases that may cause other types of pipes to rust. Additionally, aluminum pipes are strong and durable, capable of withstanding high pressures and temperature fluctuations. Unlike many other materials, aluminum pipes are also easily recyclable, making them an environmentally friendly option.

Technological advancements have led to significant innovations in aluminum piping. For example, the development of aluminum-clad steel pipes combines the strengths of both materials, providing enhanced durability and resistance to wear. New manufacturing techniques have also made it possible to produce pipes with even greater strength and longevity, making the Lenwa aluminum tube pipe suitable for some of the most demanding industrial applications.

Aluminum pipes are generally considered safe for use in both residential and commercial applications when properly installed. However, there are some safety considerations to keep in mind. Lenwa aluminium pipe should never be used with certain chemicals, such as chlorine or other corrosive substances, as these can cause the pipe to deteriorate or leak. Proper installation and adherence to manufacturer guidelines are essential to ensure the safety and longevity of aluminum piping systems.

One of the most significant advantages of aluminum pipes is their versatility. The Lenwa aluminum pipe threaded can be used for a wide range of applications, including plumbing, HVAC systems, and the transport of oil and gas. They are also widely used in the automotive industry for applications such as fuel lines. In addition, aluminum pipes are often used in construction projects for scaffolding, fencing, and railings due to their strength and lightweight properties.

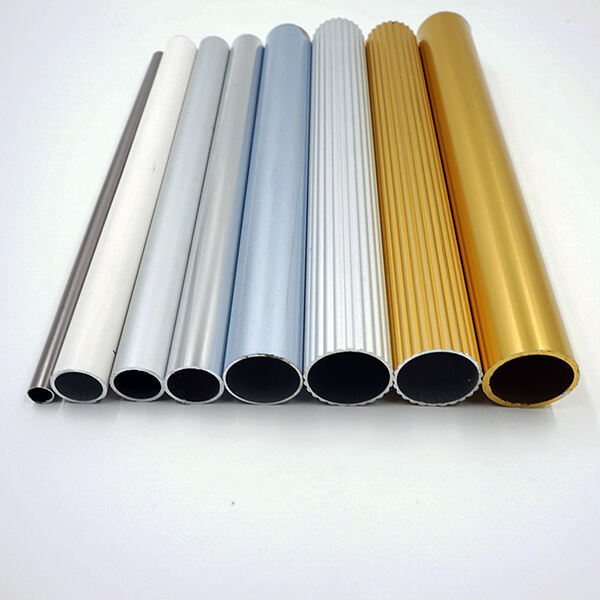

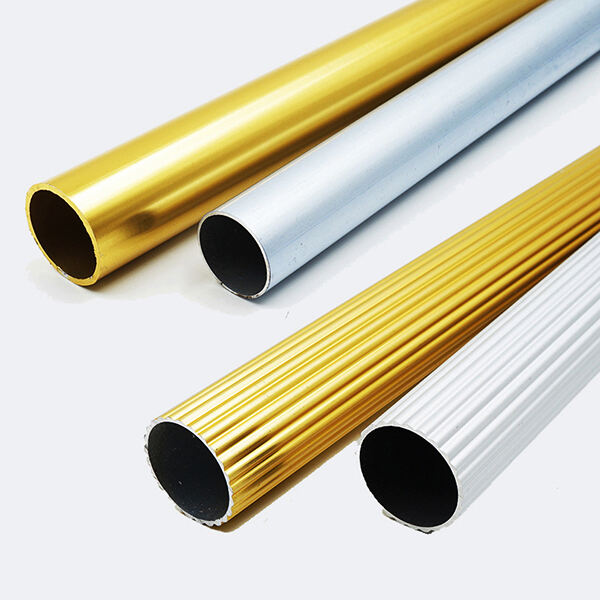

have more than 20 years of expertise aluminum extrusion surface treatment, production of aluminum Aluminum pipe. Our expertise aluminum extrusion as well as surface treatment methods like powder coating, anodizing wood grain effect guarantees the highest level of quality and endurance every product.

commitment personal service, can provide custom mold development for aluminum profiles based upon the drawings or sketches you provide, which ensures seamless integration with your specific requirements. extensive range of precision services, such as CNC milling and Aluminum pipe, as well as threading, and bent, allows to customize every aspect your design to perfection. From intricate designs to exact specifications, we offer an array of options for customization to bring your vision to life using precision efficiency.

wide range of products includes everything architectural components to decorative profiles homes. We serve a wide range of different industries applications. Our extensive portfolio can assist you in finding the ideal profile for your project, whether you need standard profiles or custom solutions. are Aluminum pipequality and innovation we constantly increase and enhance our product range in order to meet the needs changing times of our customers.

have an unparalleled manufacturing infrastructure, includes 8 aluminum extrusions lines, 1 vertical line for powder coating as well as dedicated Aluminum pipegrain anodizing lines. Additionally, workshop houses three CNC machines alongside dozens of special machining equipment. complete setup allows for an efficient precise production process to meet the requirements of our many clients.

Using aluminum pipes is relatively straightforward, especially when compared to other types of pipes. However, it is crucial to properly plan and install them to ensure safety and durability. Follow Lenwa aluminum pipe bending manufacturer instructions carefully and use appropriate tools and materials to ensure a secure and proper fit. Proper cutting, joining, and securing methods are essential to maintain the integrity of the piping system.

When selecting aluminum pipes, it is essential to consider the quality and service of the supplier. Look for suppliers with a reputation for providing high-quality products and excellent customer service. Additionally, it is crucial to choose pipes that are certified for use in your specific application, including those certified by regulatory agencies or industry standards organizations.

The applications for aluminum pipes are vast and varied, making them an excellent choice for many industrial and commercial projects. For example, aluminum pipes are commonly used in the construction of airplanes, trains, and ships due to their lightweight and durable properties. They are also popular in the oil and gas industry for transporting fluids and gases. Additionally, aluminum pipes can be used in power plants, manufacturing facilities, and even in the production of food and beverages.

Aluminum pipes offer numerous benefits, including lightweight, corrosion resistance, and durability. Technological advancements have further enhanced their performance, making them suitable for a wide range of applications. Proper use and installation are crucial to ensure safety and longevity, and selecting a reputable supplier ensures the quality and reliability of the piping system. Whether for industrial, commercial, or residential use, aluminum pipes provide a versatile and sustainable solution for various projects.

ONLINE

ONLINE