: Extrusion Shapes: The protected and method that was innovative create quality

As kids, we possibly may have played with Play-Doh or other molding materials, but what that there surely is a safer and innovative means to create quality products making use of Lenwa extrusion shapes? we will talk about the advantages of using extrusion shapes, just how to incorporate them, their applications, and the quality and service you can expect if we told.

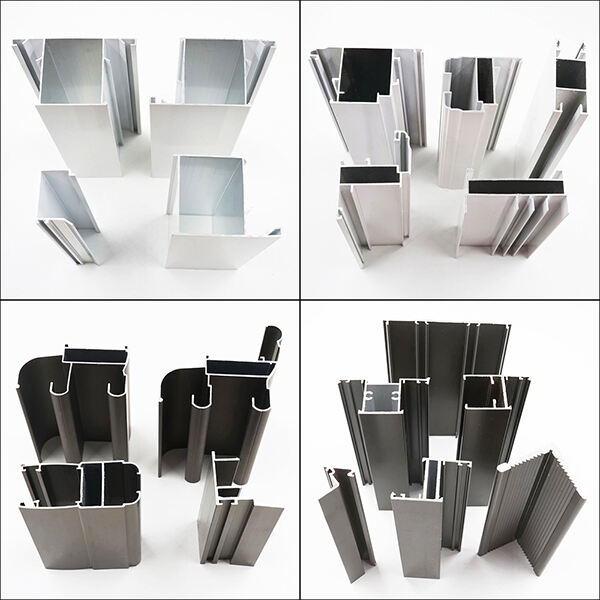

Extrusion shapes are a sort of tool that allows you to build shapes are consistent lengths of different materials, such as artificial, plastic, metal, and food. By utilizing Lenwa extruded shape, you can reduce waste, conserve time, and improve your product's quality. Below are a few features of making use of extrusion forms:

1. persistence: With extrusion shapes, you can create repeated shapes and lengths of your product, ensuring that each product was identical in dimensions and shape. That is critical in ensuring the quality of one's products and meeting the standards of your customers and industry.

2. Efficiency: Extrusion shapes is designed to manufacturing and smoother. Instead of having to determine and cut your products by hand, the extrusion process automates this process, allowing you to definitely produce most products in less time. This boost saves effectiveness are operational production costs.

3. Waste Reduction: With extrusion shapes, you are able to minimize waste by processing the exact amount of seriously to create your items. The process is most accurate, and you also can avoid overproduction and waste since the extrusion process don't depend on handbook cutting.

4. Versatility: Extrusion Shapes can be utilized with different content, including plastic, metal, and food products, making them a versatile tool for producing a variety of products.

At first glance, Extrusion Shapes might be seemingly tools are simple but in fact, Lenwa aluminum extrusion shapes are of innovation and design. Extrusion shapes are now safer to utilize, considerably automated, and require less maintenance than older designs. Right here are the good reasons being right extrusion shapes are innovative and safe:

1. Automated procedure: Extrusion shapes are manufactured to streamline the extrusion process and automate it up to a greater extent, reducing the want for manual intervention. This really helps in order to avoid accidents and injuries associated with manual labor.

2. Safety Features: contemporary Extrusion Shapes are equipped with various safety features, such as emergency stop buttons, safety guards, and lockouts, to prevent accidents and accidents.

3. Easy Integration: numerous extrusion shapes can be integrated with personal computers, enabling you to monitor the extrusion procedure and identify potential problems before they become serious. This may improve overall safety the danger of injury or damage.

Using extrusion shapes is simple and straightforward. First, you will need to choose the specified form and size for their item, which can be achieved making use of mold or die. Next, you will need to feed the material you are using into the extrusion machine, where it shall be melted and heated. Finally, the machine will push the molten material out from the Lenwa extruded aluminum channel shapes and die it into the product form that was desired. Right here are some tips on the best way to incorporate extrusion:

1. select the Appropriate Die or mildew: selecting the die that was right mold critical in creating the desired shapes and lengths for the item.

2. Follow Safety directions: Make sure to follow safety instructions and guidelines when making use, as this can ensure operations are injury-free.

3. Follow upkeep directions: Proper maintenance of extrusion shapes is essential to improve their longevity. Make certain to follow combined with the manufacturer's instructions on maintenance, cleaning, and fix with this equipment.

When using Extrusion Shapes, you need to ensure that you obtain both quality and services are great. Here are some conditions are plain kept at heart when looking for quality extrusion shapes:

1. Material Quality: Lenwa aluminum channel shapes is essential that the extrusion shape you employ is made of high-quality materials that can withstand the intensity associated with the extrusion process. This will promise an item that try long-lasting brings quality results.

2. support and provider: When selecting an extrusion shapes provider, make sure to choose company which will offer after-sales are good and support. This includes support are technical, and repair services.

3. Product Warranty: A guarantee is an extremely consider that was feature is important purchasing extrusion forms. A quality is great should come having a warranty or guarantee, which can supply peace of mind and services to avoid the expenses linked to unforeseen breakdowns.

have more than 20 years of expertise aluminum extrusion treatment Extrusion shapes, and the production of aluminum profiles. From precise extrusion, precise technique for finishing surfaces such as anodizing, powder coating, and wood grain effects our experience ensures each product meets the highest standards of quality and durability.

wide range products includes everything from architectural parts profiles for home decoration. serve a wide range of different industries and applications. broad Extrusion shapeswill assist you in finding the ideal profile to meet your needs, whether you require regular profiles or bespoke solutions. are committed innovation and quality which is why we continuously develop and improve our products to meet the changing needs of our clients.

provide a custom-designed mold aluminum profiles is designed based on samples or Extrusion shapes. will ensure an effortless integration of your requirements. Our broad range of high-precision solutions, such as CNC milling and punching, as well as threading bent, allows us to modify every aspect of your design to highest quality. We offer a broad range of customization options, from intricate designs to precise specs.

have an unparalleled manufacturing infrastructure, which includes eight lines aluminum extrusions, 1 powder coating vertical line, dedicated wood Extrusion shapesanodizing production lines. Additionally, we have three CNC machines numerous specially-designed equipment. This vast setup is guaranteed to provide precise and efficient production meets various requirements of our customers.

E

Extrusion forms are commonly discovered in different industries, such as the food industry, construction industry, and automotive industry. Right here are some examples of exactly how Lenwa extruded aluminum shapes forms are used in different applications:

1. Food Industry: Extrusion shapes is put to generate forms that will vary forms of food, such as for instance pasta, cereal, and treats.

2. Construction Industry: Extrusion shapes are used to generate building that was different as for instance pipes and window frames.

3. Automotive Industry: Extrusion shapes may play job are critical the manufacturing of various car components, such as molds and frames.

ONLINE

ONLINE