The Advantages of Using Extruded Aluminum Channel Shapes

Are you looking for usually versatile and safe material to use in construction or manufacturing projects? Look no further than extruded aluminum channel shapes manufactured from Lenwa. These shapes, are actually known as extrusions, those innovative solutions offer numerous advantages for wide variety of applications. Let's explore these advantages further.

Extruded aluminum channel shapes of Lenwa are truly durable and lightweight, making easy to handle and transport. They are also resistant to corrosion and wear, making ideal for outdoor or harsh environments. This extruded aluminum drawer pull can also save you money in the long run, as they really require a little upkeep maintenance and also have a long lifespan.

Extruded aluminum channel shapes are a good result of innovative manufacturing processes and technologies. The Lenwa extruded aluminum shapes are really created by forcing aluminum through die, resulting consistent as well precise shapes. This allows for customization and versatility, as extrusions can created in various shapes and sizes to fit specific needs of your project.

Safety is truly a top priority when it comes to construction and manufacturing. Fortunately, extruded aluminum channel shapes offer several safety benefits. The Lenwa channel shapes are actually as non-combustible, meaning do not ignite or spread flames. They are also non-toxic, meaning do not contain harmful substances that can potentially harm workers or the environment.

Extruded aluminum channel shapes of Lenwa can used in a variety of applications, such as building and construction, manufacturing, and even transportation. This can really use as support beams, frames, extrusion brackets, structural components, and more. Those are even used in production of electronics, such as computer cases and cell phone frames.

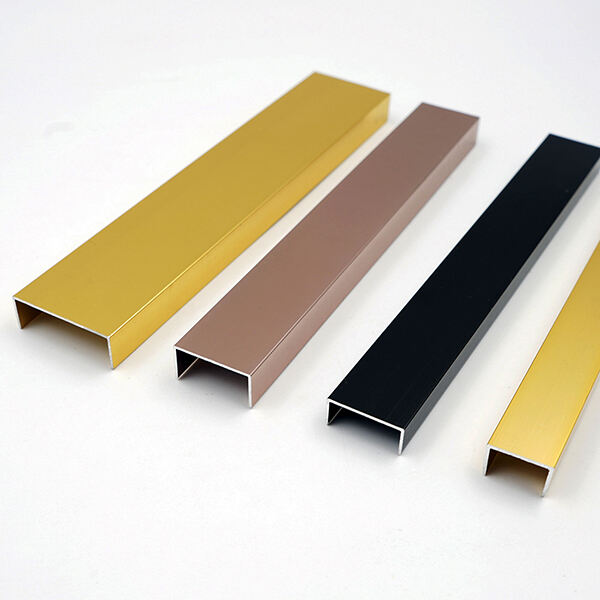

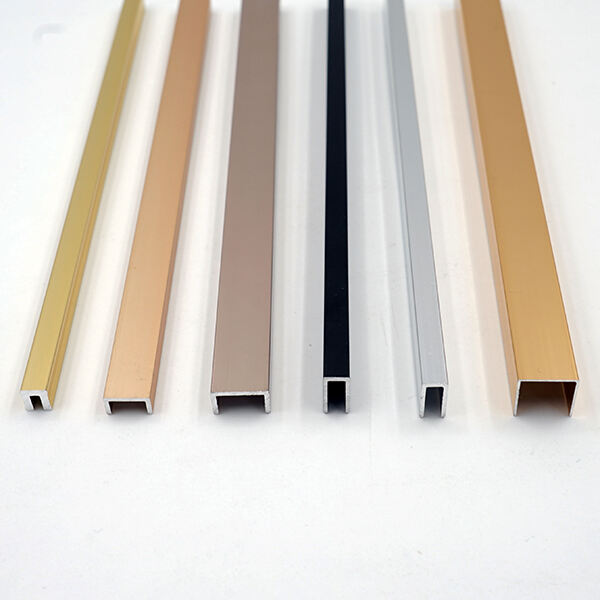

have over 20 years experience aluminum extrusion surface treatment manufacturing aluminum profiles. From precise extrusion, precise finish Extruded aluminum channel shapeslike anodizing, powder coating, wood grain effects, our expertise ensures every product meets the highest standards in terms of durability and quality.

wide range of products covers everything architectural elements decorative profiles for Extruded aluminum channel shapes. cater to many different industries and applications. vast portfolio of products will assist you in finding the ideal profile to meet your needs, whether you need standard profiles or customized solutions. committed to quality and innovation, as we continue to improve and expand our offerings in order to meet the requirements of our customers.

commitment personal service, can provide custom mold development for aluminum profiles based upon the drawings or sketches you provide, which ensures seamless integration with your specific requirements. extensive range of precision services, such as CNC milling and Extruded aluminum channel shapes, as well as threading, and bent, allows to customize every aspect your design to perfection. From intricate designs to exact specifications, we offer an array of options for customization to bring your vision to life using precision efficiency.

With 8 extrusion lines of aluminum a vertical powder coating line well as dedicated anodizing wood grain production lines boast unmatched manufacturing facilities. In addition, our workshop houses three CNC machines as well as a variety of specially-designed machining equipment. complete setup will ensure highest Extruded aluminum channel shapesand efficiency in production and meets varied needs of our customers.

Using extruded aluminum channel shapes of Lenwa are really easy as simple. They can cut to size using a saw or grinding wheel, and also can drilled or tapped to create screw holes. They can also easily welded or joined with any other pieces to create larger structures. Some extrusions even have slots or grooves to allow for easy attachment of those components.

Extruded aluminum channel shapes built by Lenwa are truly made from high-quality materials and go through rigorous quality control measures to ensure strength and durability. The extruded aluminum enclosure profiles are tested for mechanical properties, corrosion resistance, as well as dimensional accuracy before being sold to customers. This means that you can trust your extrusions will meet your expectations and stand up to test of time.

As mentioned earlier, Lenwa standard extruded aluminum profiles or shapes can be used in a wide variety of applications. A few examples include:

- Building and Construction: For structural components, these window door frames, support beams, and more

- Manufacturing: As frames, the extrusion brackets, conveyor systems, and more

- Transportation: For truck bodies, those trailer frames, and so much more

ONLINE

ONLINE